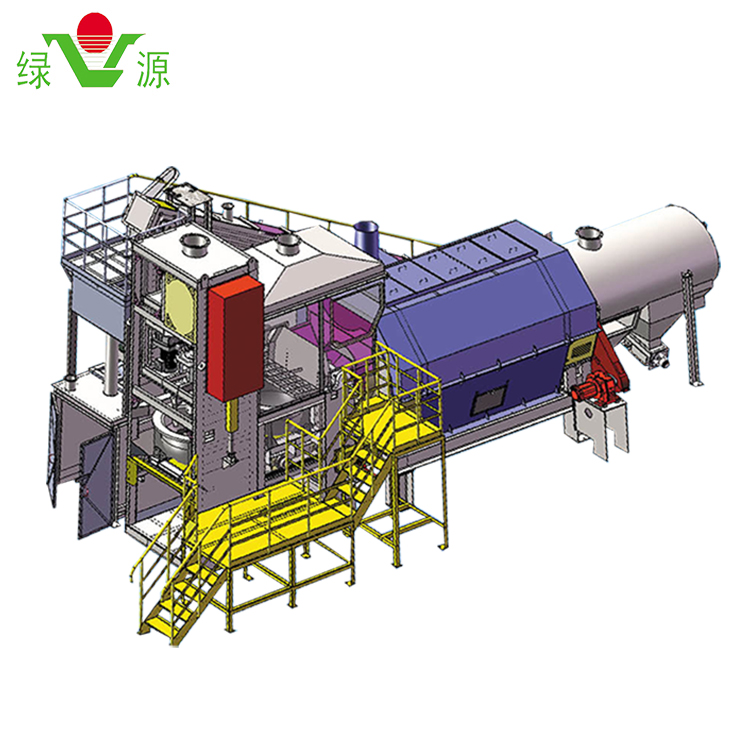

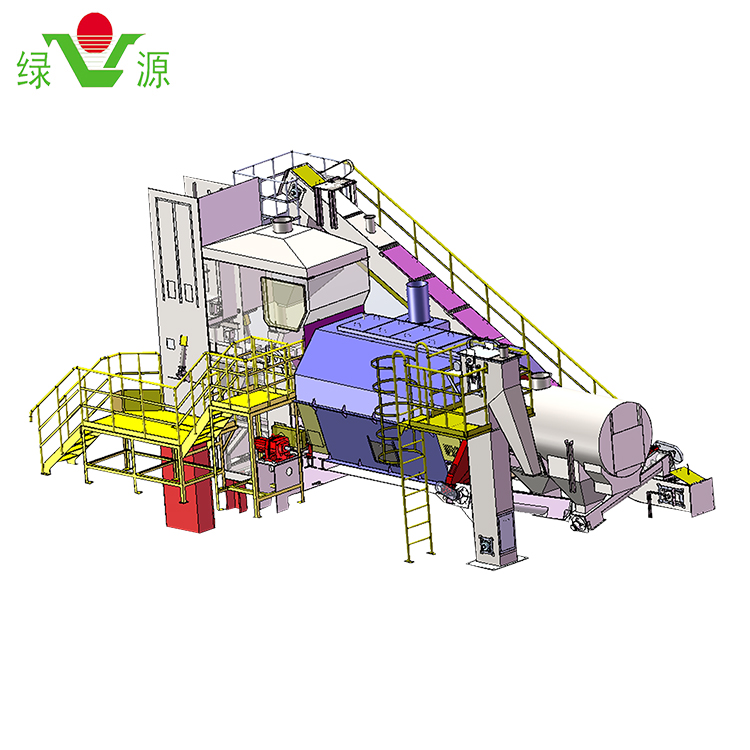

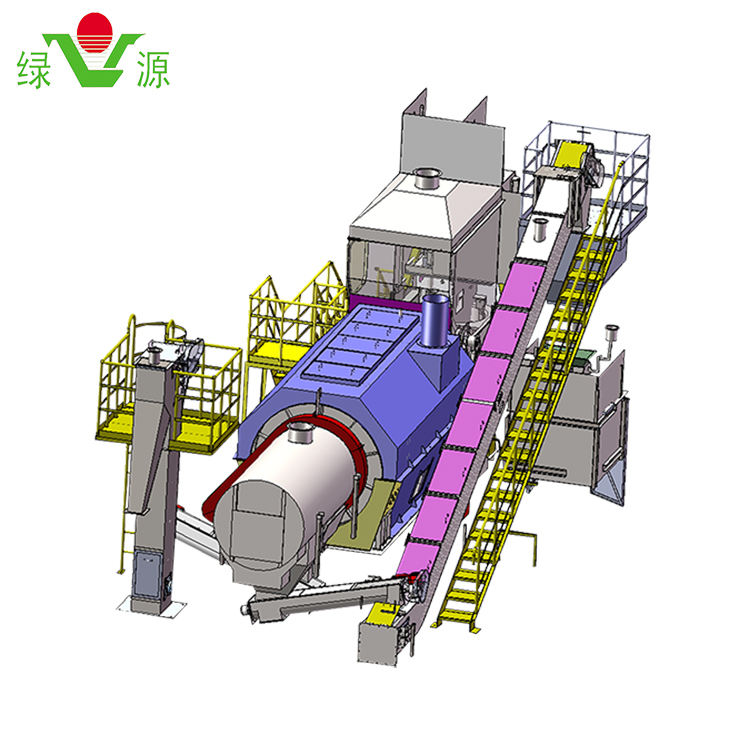

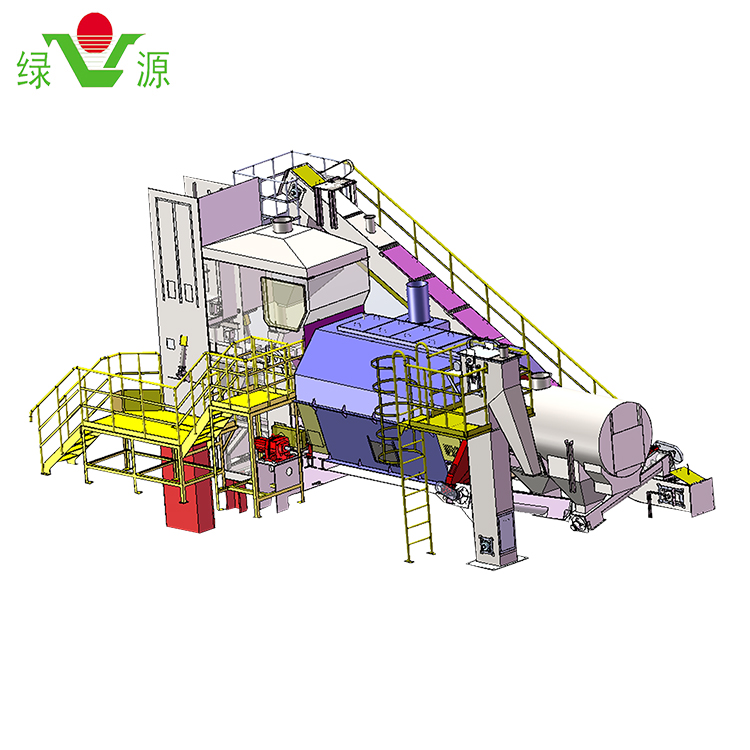

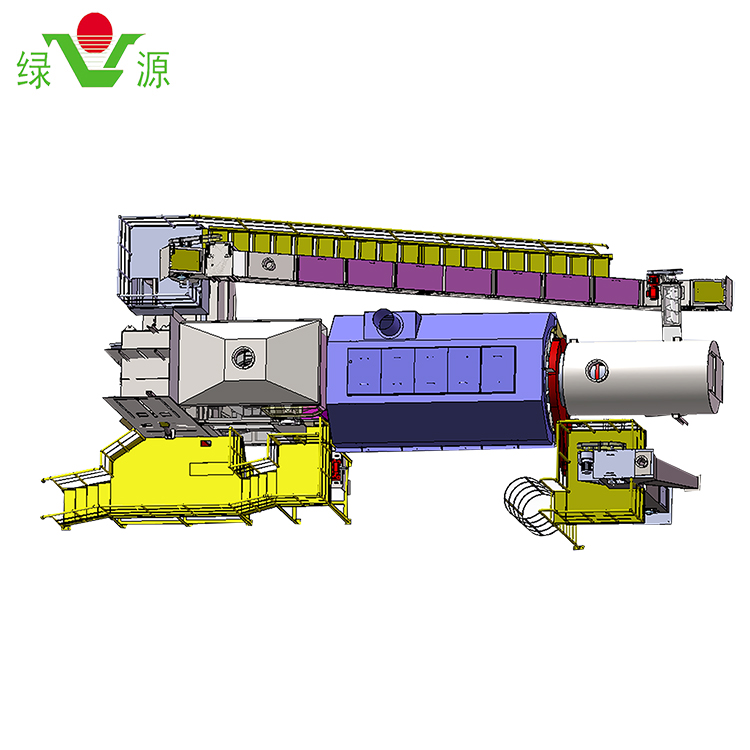

Eco-friendly type full automatic aluminum dross machine

Eco-friendly type full automatic aluminum dross machine

Advantages of Automatic Aluminum Slag Processing Equipment

Advantages of Automatic Aluminum Slag Processing Equipment

1.The area is small and the form of the foundation is relatively simple, which reduces the additional expenditure of some foundations.

2. The environmental protection performance is better: because the mobile aluminum slag pot is used to connect the aluminum slag to the furnace mouth and directly put into the ash-frying equipment, the aluminum slag separation operation is performed. Reduced the step of pouring hot aluminum slag directly into the fixed aluminum slag pot, and also avoided a large amount of soot generated by tipping (some of the soot is caused by the combustion of liquid aluminum and oxygen contact and combustion).

3. High Degree of Automation: After the separation of aluminum and water, the method of automatic tipping is used to introduce the hot residue into the cooling barrel through the chute (reducing the requirements for the difference in foundation height); The medium-grain aluminum residue after screening passes through the spiral conveyors, scraper and put the machine together with the ash job is automatically added to the next pot in the particles used, the benefits of (recycled particles: A. can reduce the temperature of a high temperature aluminum dross in order to achieve the most Better frying ash temperature; B. Re-extract the available aluminum in the middle ash to increase the recovery rate; C. Reduce the probability of crusting).

4. It is more convenient to replace the wearing parts: the pot, mixing blade and top in the ash frying operation can be flexibly transported out/disassembled.

5. The operation process of the whole set of aluminum slag processing equipment is controlled by PLC program. The operator can complete the control of the equipment only through the touch screen/remote control, which greatly improves the work efficiency.