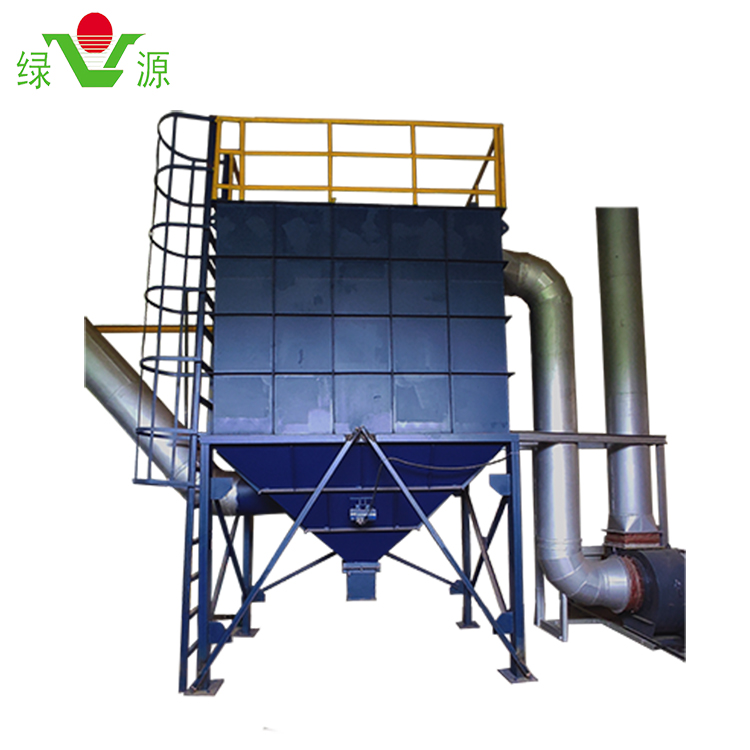

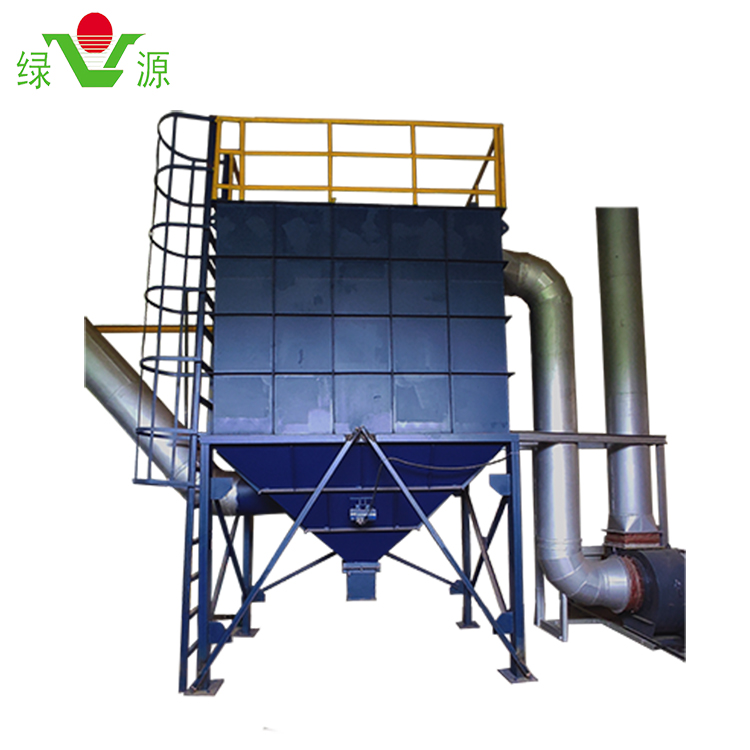

Industrial buffing machine marble cyclone bag dust collector system

Industrial buffing machine marble cyclone bag dust collector system

1. The dust removal effect is good, and the dust concentration for processing fine dust can also be far lower than the national emission standard.

2. It has strong adaptability and has a good dust removal effect on various types of dust.

3. The specifications are diversified, with large and small air volume dust collectors, and the application is very flexible. ,

4. Easy to recycle dry materials, no sludge treatment, sewage pollution and corrosion problems.

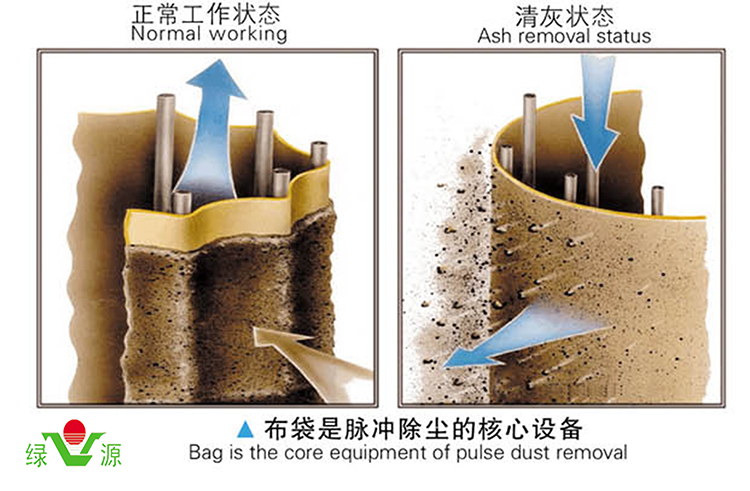

Pulse bag filter

The physical and chemical properties of industrial dust are different, and the nature and degree of harm to the human body are also different. The pulse bag filter developed and produced by our company from the basic concept of protecting labor safety and health production is an application. A very extensive dust removal system, without changing the physical characteristics of the dust, ensures more thorough dust removal, finer filtration and more convenient maintenance. It has been applied to various industries and is suitable for metallurgy, woodworking, building materials, cement, machinery and chemical engineering, Power, light industry dust gas purification and material recovery.

Equipment structure:

1. The blowing pipe is responsible for blowing and diversion.

2. The electromagnetic pulse valve is responsible for opening and closing the compressed air.

3. Air bag, store compressed air.

4. The dust bag is the core component of dust filtering.

5. Dust removal net cage, support dust removal cloth bag.

6. The controller is responsible for controlling the opening and closing of the compressed air and the ash discharge system.

7. The conveyor belt air shutter (electric air shutter) continuously discharges the material in the dust collector in time.

8. The muffler reduces the noise emission of the motor.

9. Control electric box, control and start-stop equipment.

10. The fan increases the gas pressure to discharge the gas.

Working principle: The dust-containing gas enters the main pipe from each dust removal branch pipe and enters the cyclone dust collector. After filtering a part of the coarse particle dust, it enters the bag filter inlet and enters the ash hopper from the dust collector air inlet. Due to the gravity effect of the dust, The coarse particles directly settle in the ash hopper under the action of gravity, and the remaining dust-containing gas rises to the middle box through the deflector, and is evenly distributed in the filter bags. At this time, the dust is blocked on the outer surface of the filter bag, and the filtered clean air enters the upper box through the bag flower plate and is discharged from the exhaust duct. When the dust accumulation on the outer surface of the filter bag thickens to a certain extent (set time). The pulse control device sends a signal to close the air inlet valve of the first chamber, and the blowing device starts to work. The compressed air is sprayed to the filter bag through the pulse valve and the nozzle on the blowing pipe in a very short time sequence, so that the filter bag is vibrated under the action of vibration. , The dust attached to the outer surface of the filter bag falls off the filter bag and falls into the ash hopper. When the dust removal in the first chamber of the dust collector is completed, open the first chamber air inlet valve and close the second chamber air inlet valve, and the first chamber participates in filtering Work, the second room began to conduct offline cleaning, and from then on, proceeded from room to room. Since offline cleaning was realized, the cleaning effect was improved.

The entire dust removal control adopts PLC programmable controller control, and the control mode is divided into automatic timing and manual control.

The selection of air volume of dust collector: The air volume of dust collector refers to the volume of gas that the dust removal equipment can purify in a unit time. The air volume of small dust collectors is as small as a few cubic meters per hour, and the air volume of large and medium dust collectors can reach hundreds of Ten thousand cubic meters per hour, the air volume of the dust collector determines the working efficiency of the dust collector and the difference in the size and model of the dust collector.

The air volume selection of the dust collector should be reasonable:

1. If the dust removal air volume is selected too large, the equipment area and investment will increase.

2. If the dust removal air volume is selected too small, the filter bag will be easily blocked when the dust collector is operated under the state of excess air volume, the life will be shortened, the pressure loss will increase, and the dust removal effect will be reduced. The pulse dust removal produced by our company The air conditioner has a variety of specifications, and the size of different specifications is determined by the customer according to the air volume to be processed.

advantage:

1. The dust removal effect is good, and the dust concentration for processing fine dust can also be far lower than the national emission standard.

2. It has strong adaptability and has a good dust removal effect on various types of dust.

3. The specifications are diversified, with large and small air volume dust collectors, and the application is very flexible. ,

4. Easy to recycle dry materials, no sludge treatment, sewage pollution and corrosion problems.

Acceptance index

1. The dust collection of each suction hood is ≥90%.

2. Dust removal efficiency ≥99.5%

3. Dust emission concentration ≤50mg/㎥

4. Ringelmann blackness: 1 degree