Double-chamber side pool aluminium melting furnace双室测井熔炼炉

Double-chamber side pool aluminium melting furnace双室测井熔炼炉

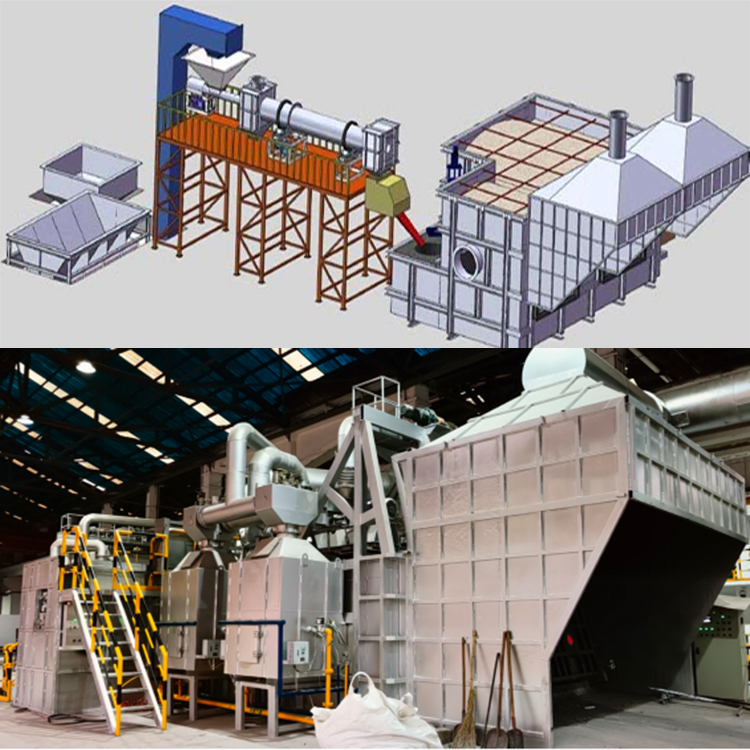

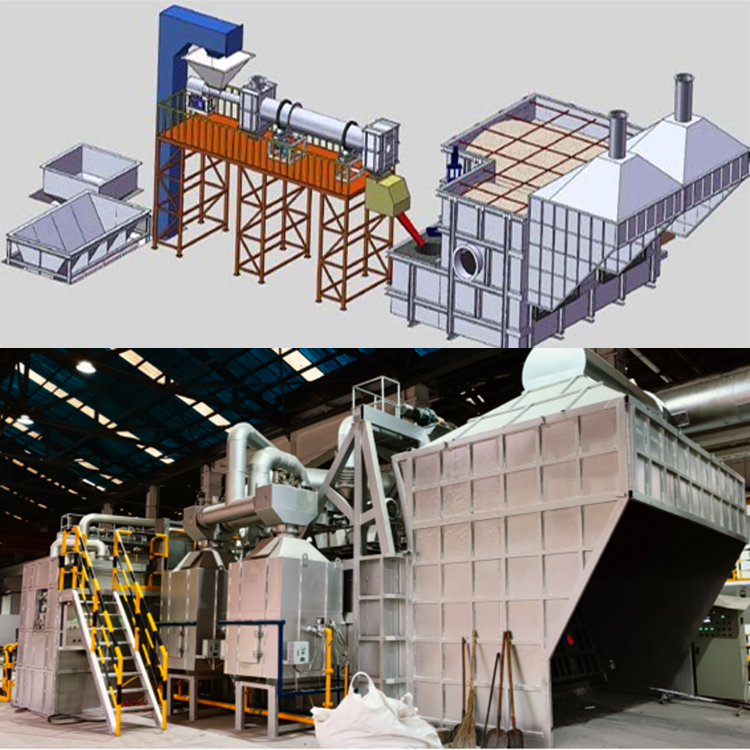

The double-chamber side pool aluminum melting furnace retains all the functions of the aluminum melting furnace itself and builds an open side pool on the side wall or rear wall of the aluminum melting furnace, installing an aluminum water mechanical pump. Larger-grained, block-shaped and strip-shaped waste aluminum raw materials are normally fed from the furnace mouth of the aluminum melting furnace by forklifts. The thin and light crushed waste aluminum raw materials are continuously and automatically conveyed into the feeding vortex well for melting through the pretreatment line. With the power of the mechanical pump for molten aluminum, the high-temperature molten aluminum is drawn out of the aluminum melting furnace, passes through the mechanical stirring well, and enters the feeding vortex well to melt the thin and crushed waste aluminum raw materials, turning them into low-temperature molten aluminum. Then it flows back into the aluminum melting furnace for reheating and temperature increase, thus completing the circulation flow of the high-temperature molten aluminum to melt the waste aluminum raw materials, achieving the process of melting the thin and crushed waste aluminum raw materials without any open flame. Greatly reduce the oxidation and burning loss of waste aluminum raw materials and increase the harvest rate of waste aluminum. The single-chamber side pool aluminum melting furnace features low oxidation loss, high aluminum water recovery rate, low slag production, good environmental protection effect, high melting efficiency, low energy consumption, mechanical continuous feeding and melting, and reduced labor intensity for workers. It is currently recognized worldwide as the most mature technology suitable for online recovery of aluminum shavings.

双室侧池熔铝炉,保留熔铝炉自身所有功能,并在熔铝炉侧墙或者后墙上建造一个敞开的侧池,安装铝水机械泵。

大颗粒一些的块状条状废铝原料,通过叉车从熔铝炉炉口正常投料轻薄破碎废铝原料,通过前处理线连续不断地自动输送进入投料漩涡井熔化。借助铝水机械泵的动力,

高温铝水从熔铝炉内抽出,经过机械搅拌井,进入投料漩涡井,熔化轻薄破碎废铝原料,

变成低温铝水,再流入熔铝炉,重新再次加热提温,从而完成高温铝水熔化废铝原料的循环流动,实现轻薄废铝原料始终不见明火熔化的过程,

极大降低废铝原料的氧化烧损,提高废铝收成率单室侧池熔铝炉具有氧化烧损低,铝水回收率高,产渣量少,环保效果好,熔化效率高,能耗低,机械化连续投料熔化,降低工人劳动强度等的特点,

是目前世界上公认的最适合铝屑在线回收的成熟技术。

The double-chamber side pool aluminum melting furnace retains all the functions of the aluminum melting furnace itself and builds an open side pool on the side wall or rear wall of the aluminum melting furnace,

installing an aluminum water mechanical pump. Larger-grained, block-shaped and strip-shaped waste aluminum raw materials are normally fed from the furnace mouth of the aluminum melting furnace by forklifts.

The thin and light crushed waste aluminum raw materials are continuously and automatically conveyed into the feeding vortex well for melting through the pretreatment line. With the power of the mechanical pump

for molten aluminum, the high-temperature molten aluminum is drawn out of the aluminum melting furnace, passes through the mechanical stirring well, and enters the feeding vortex well to melt the thin and crushed

waste aluminum raw materials, turning them into low-temperature molten aluminum. Then it flows back into the aluminum melting furnace for reheating and temperature increase, thus completing the circulation flow

of the high-temperature molten aluminum to melt the waste aluminum raw materials, achieving the process of melting the thin and crushed waste aluminum raw materials without any open flame. Greatly reduce the

oxidation and burning loss of waste aluminum raw materials and increase the harvest rate of waste aluminum. The single-chamber side pool aluminum melting furnace features low oxidation loss, high aluminum

water recovery rate, low slag production, good environmental protection effect, high melting efficiency, low energy consumption, mechanical continuous feeding and melting, and reduced labor intensity for workers.

It is currently recognized worldwide as the most mature technology suitable for online recovery of aluminum shavings.