绿源集团

Lvyuan Group

绿源集团

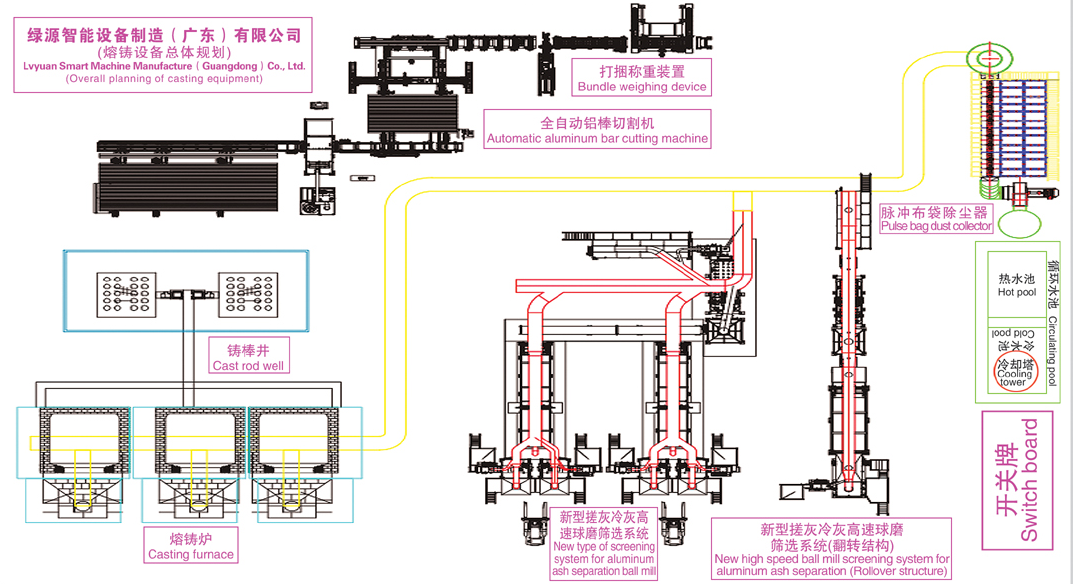

Lvyuan Smart Machine Manufacture(Guangdong)Co.,Ltd. was established in 2005. It is a professional manufacturer of aluminum

ash recycling production line, cold ash ball mill screening machine, rotary furnace, aluminum ash separator,For aluminum bar saws,

aluminum sandblasting machines,refining agents, metal structure manufacturing, chemical reagents and auxiliary manufacturing, etc.,

Lvyuan Group covers an area of over 90,000 square meters and employs more than 400 people.Among them, there are 12 technical

engineers, 6 sales engineers, 18 sales clerks, and more than 30 technical backbones in the workshop. The annual output value exceeds

500 million yuan. The company’s integrity is based,The quality of Jinjian is well-known. .

For more than ten years, Lvyuan has been seeking development and innovation. In 2010, Lvyuan started group operation and

development, from aluminum waste products into the refining agentslagging agent after the rotary furnace,After the aluminum ash

is out of the furnace, the ash frying machine, the ash cooler, the ball milling and screening machine, the environmental protection

dust collector, the filter plate used for the aluminum water to enter the filter box, and the automatic aluminum rod saw after the

aluminum water is discharged from the well.The products operated by the Lvyuan Group already include all the equipment, auxiliary

materials, additives, etc. required for the entire aluminum melting and casting process, and a one-stop solution for a systematic

product structure.The brand awareness of Lvyuan has started to rise in the

industry. The quality of Jinjian has created the road of Lvyuan brand.

Lvyuan Smart Machine Manufacture(Guangdong)Co.,Ltd.was established in 2005, located in Nanhai District, Foshan City,

Guangdong Province, specializing in the production of aluminum (zinc) ash cooling ball mill separators.Automatic aluminum

ash recovery production line and other melting and casting equipment,fluxes and element additives.

Foshan Lvheng Machinery Co., Ltd. was established in 2008, specializing in the production of aluminum sandblasting machines,

aluminum automatic interrupting saws, tractors, copper and aluminum automatic multi-rod pressing machines,The technical

strength and market competitiveness of the products are in a leading position in China.

Foshan Lvyuan Huachuang Environmental Protection Equipment Technology Co., Ltd. was established in 2010. It is

a member of the Guangdong Environmental Protection Association and specializes in industrial waste gas and dust

pollution treatment and engineering construction.

In 2011, Foshan Sanshui Jinjianli Metal Products Co., Ltd. was established, specializing in the production of aluminum-silicon

alloy ingots and ADC12 alloys of various brands.

In 2013, Guangxi Xingye County Xinluyuan Metal Material Co., Ltd. was established, specializing in the production of

ceramic filter plates, aluminum fluxes and element additives.

In 2022, Green Origin Intelligent Equipment (Guangdong) Co., Ltd. was established, mainly engaged in the R&D, maintenance,

production and sales of intelligent equipment and mechanical equipment.

Lvyuan’s product quality keeps improving, strict quality control, timely production and delivery, and perfect pre-sales and

after-sales services have allowed customers’ satisfaction rates to rise steadily.Gold and silver cups are not as good as customers'

reputation, and Lvyuan people are never proud. Luyuan Group has obtained a series of product appearance patents and utility

model professions on the basis of technological innovation.Innovation is the driving force of the group's continuous progress.

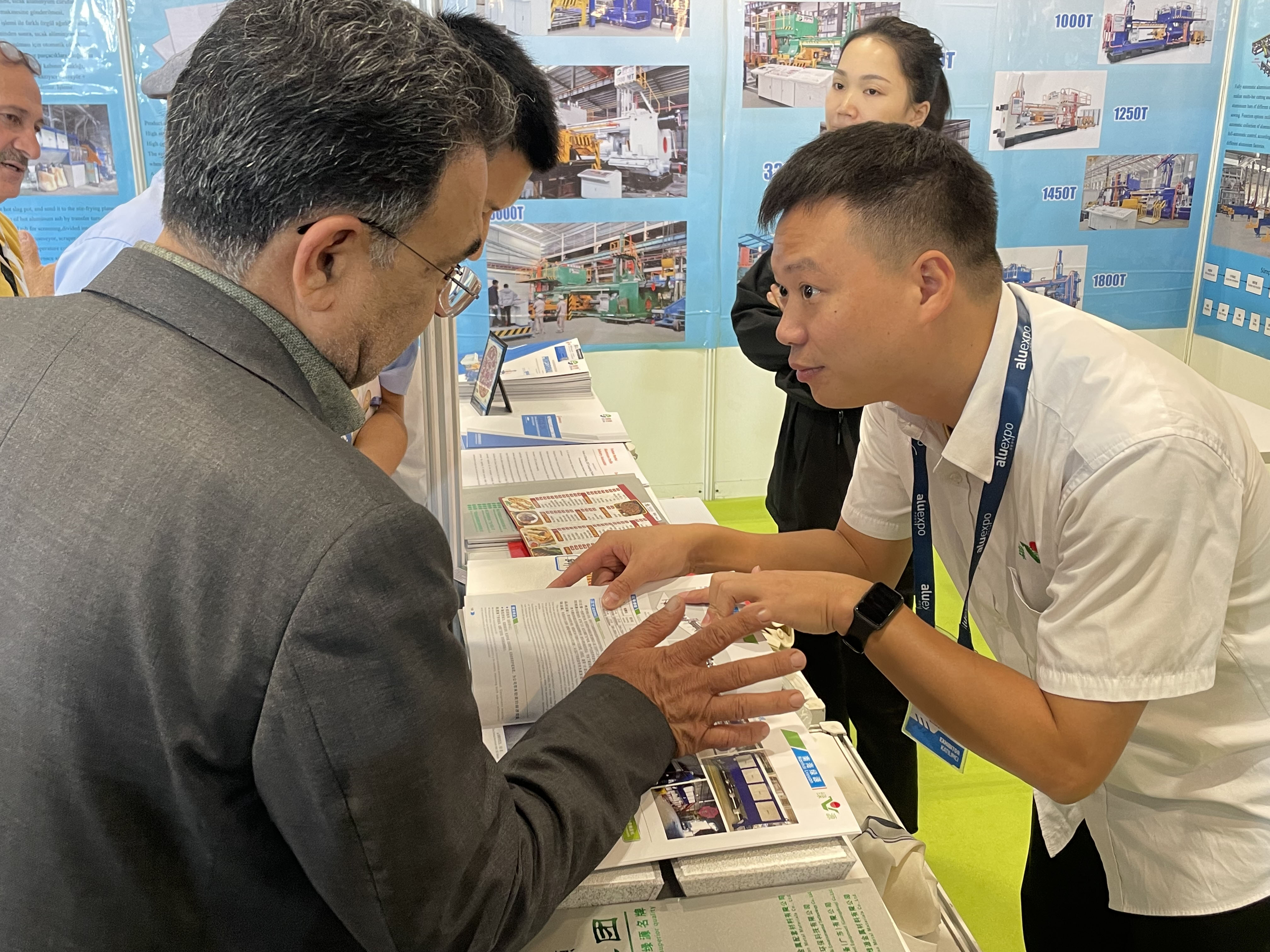

Lvyuan Group actively participates in industry exchanges, exhibitions, production technology and other industry events. In

the long-term development process of Lvyuan Group, with excellent product quality, good product performance,Leading

technical advantages and many large domestic aluminum factories and melting and casting plants have established long-term

good partnership relationships. Luyuan Group sincerely welcomes domestic and foreign customers to visit our company.Visit

and technical exchange!

GENERAL CONTRACTING PROJECT

GENERAL CONTRACTING PROJECT

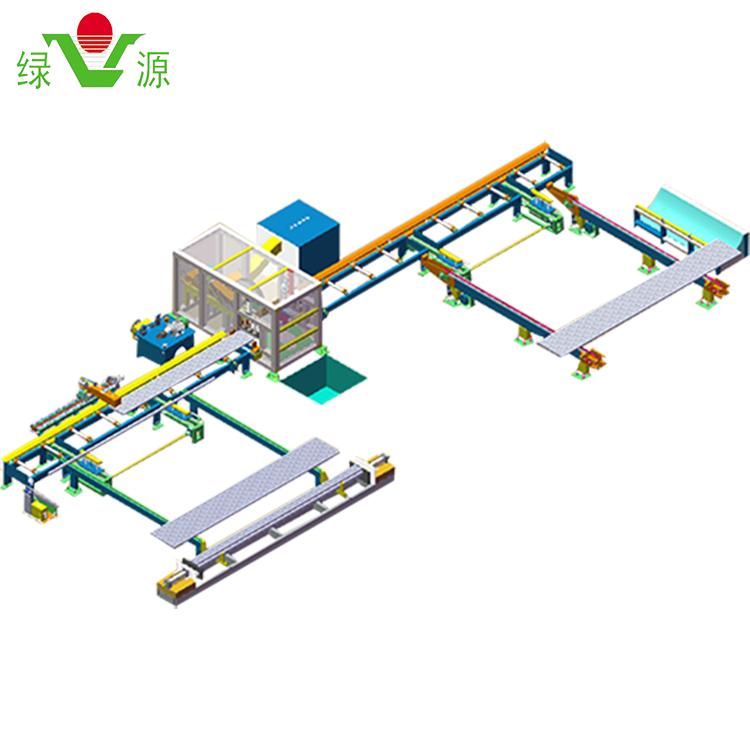

The ingot production line can achieve functions such as automatic distribution and casting of aluminum liquid,surface scrapingof aluminum liquid, adjustable casting sped.automatic ingot tapping and demolding, automatic stacking and weighing byrobots,automatic transmission of weighing data. automatic printing of labels and labeling (or automatic laser marking), etc.

Advantages of ingot production line: High degree of automation not only enables fewer people to operate,reduces laborcosts,and reduces safety issues such as burns and collisions during the production process, but also improves production efficiency,aluminum ingot weight uniformity,no large or small heads, and smooth surface enhancing the company's image.

Cooling methods include bottom mold cooling and spray cooling. Mold bottom cooing refers to the cooling method where thebottom of the mold is immersed in water and the aluminum ingot does not come into contact with water, with a cooling water volumeof approximately 100 m3h; spray cooling refers to a cooling method in which cooling water is directly sprayed onto the aluminumingot, with a cooling water volume of approximately 30 m3/h.

The regenerative aluminum melting furnace is an efficientand environmentally friendly aluminum melting equipment,mainly used for aluminum smelting, casting and continuouscasting. This equipment adopts regenerative heat exchangetechnology. Equipment advantage ●Efficient and energy-saving: adopting heat storage heat exchange technology can fully utilize heat and reduce energy consumption. ●Environmental protection and safety: Adopting a closed furnace to reduce smoke and dust emissions and meet environmentalrequirements ●Easy to operate: highly automated, easy to operate, and can achieve one click operation. ●Durable and reliable: Made of high-quality materials, the equipment has a long service life and high reliability. |

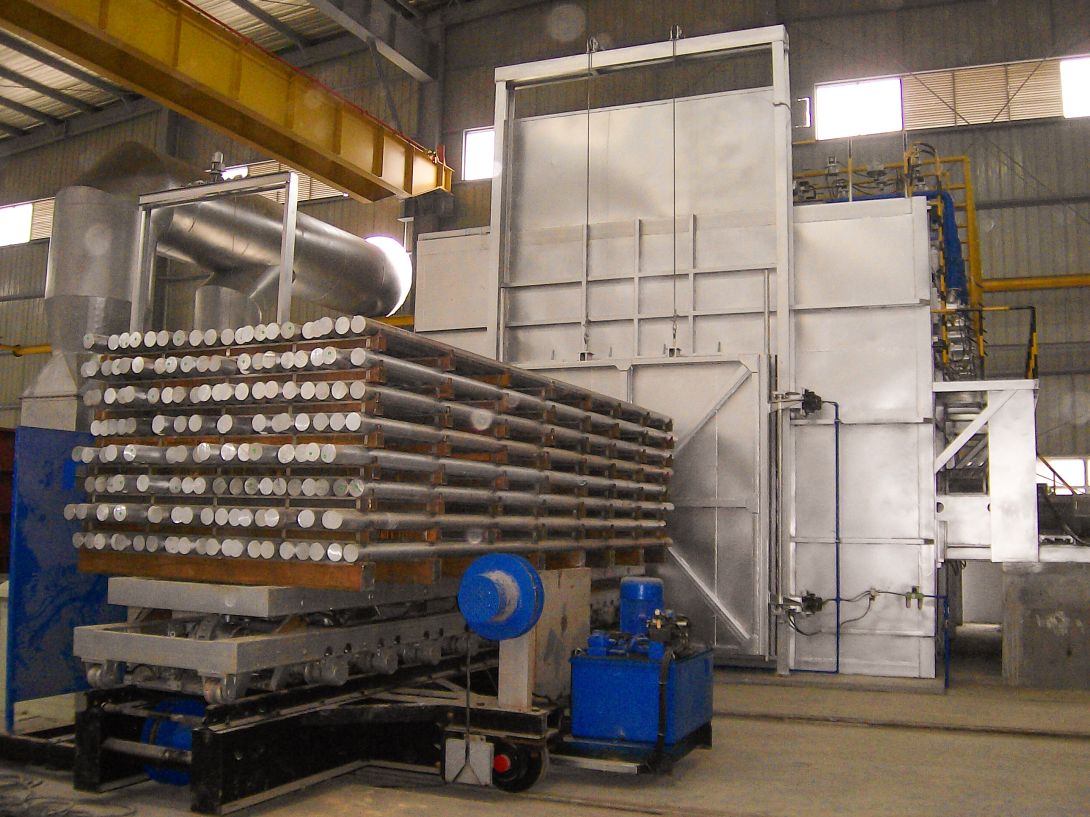

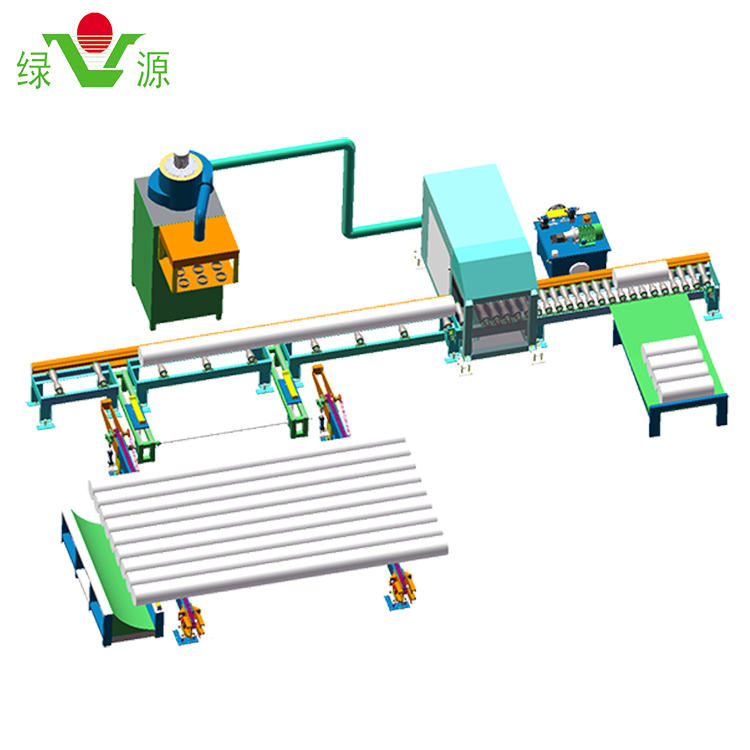

Homogenizing Furnace

|

Specialized equipment for post-casting heat treatment of aluminum rods,aimed at eliminating residual stresses and uneven metallographic structures generated during casting,thereby improving the extrusion processing performance in subsequent processes,enhancing production efficiency, and elevating thequalityofaluminumprofile product

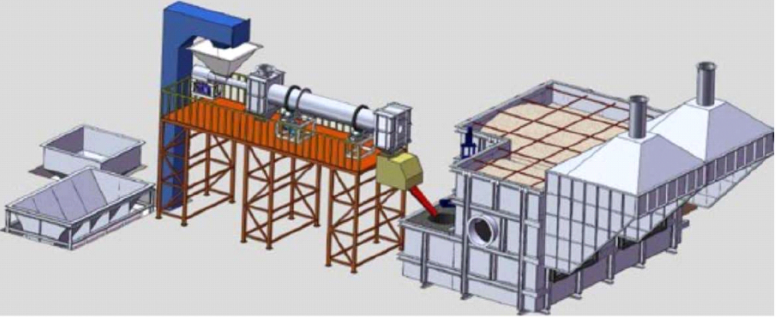

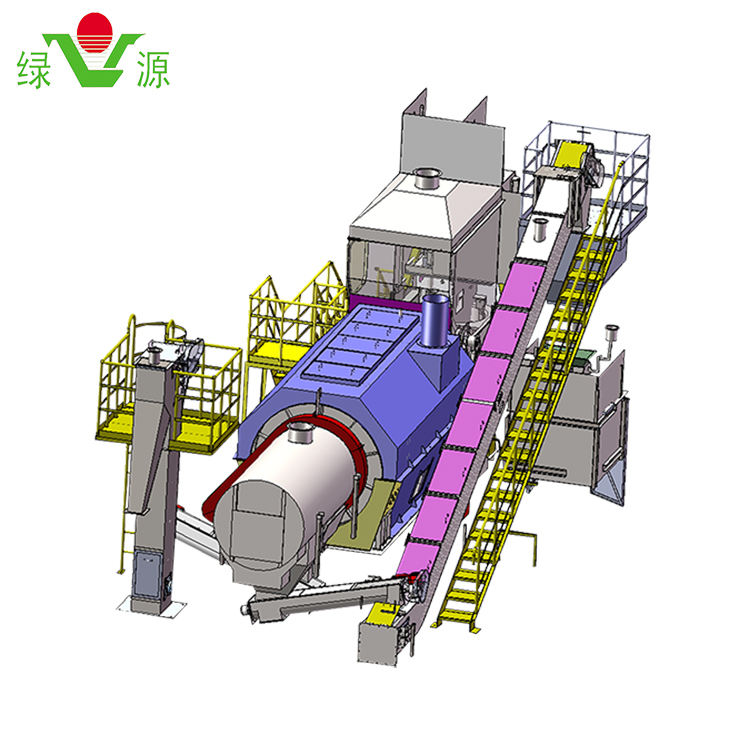

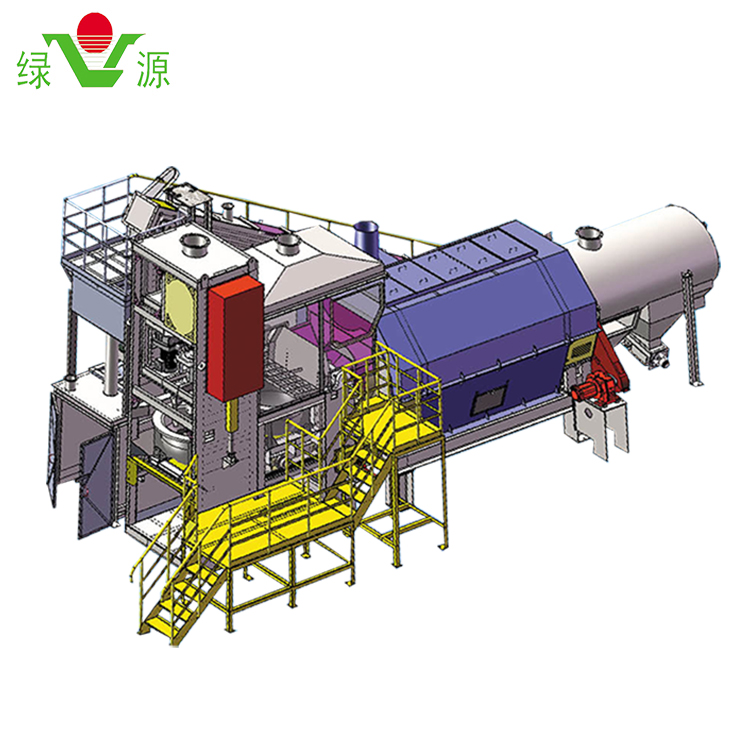

Rotary furnace(without burner) Rotary furnace for heat treatment furnace in slag rake, stirring by rotating the rotary furnace the aluminum ash in high temperature(occasionally and harmonic agent),in order to improve the aluminum melting rate and aluminum water temperature, water viscosity of aluminum,aluminum liquid and aluminum ash peel,The aluminum liquid is precipitated to achieve secondary recovery of the aluminum liquid in the aluminum slag,can make the aluminum content in the aluminum slag dropped to below 15%.The current models are 6 tons, 8 tons and 10 tons 15 tons | Rotary furnace(with burner) Smelting type rotary furnace is a simple installation with melting aluminum metal function of the furnace,its characteristics of 360 degree rotation of the furnace more uniform heating,equipment installation is simple,convenient transportation,safety and energy saving,conventional specifications for 3 tons-15 tons,according to different tonnage and melting speedequippedwiththe correspondingcombustion system |

The dual chamber side pool aluminum melting furnace consists of a heating chamber, a feeding chamberand a side pool. Heating chambers are usually equipped with high-power regenerative combustion systemequipment to increase the temperature of aluminum water; The feeding room is usually equipped with low.power conventional burners, which play a role in bumning the black smoke of the feeding and keeping thealuminum water warm and insulated: The side pool is composed of mechanical pump well, vortex feeding welaluminum water circulation pump, precast black smoke incineration bell cover for casting material, precastcirculation channel for casting material, refractory material for side pool lining, side pool steel structure, maindrain hole for cleaning aluminum water, control box for aluminum water mechanical pump, and operatingplatform for side pool. The aluminum water circulation pump installed on the side pool drives the circulation otaluminum liquid between the heating chamber, mechanical pump wel, vortex feeding well, and feedingchamber through forced stirring, and forms an aluminum water centrifugal vortex in the vortex feeding well tobury the aluminum chips into the vortex, The aluminum chips are melted by high-temperature aluminum waterinstead of high-temperature oxygen-containing flame, thus achieving the melting of aluminum chips. Lowburn recovery process. As shown in the above fiqure.

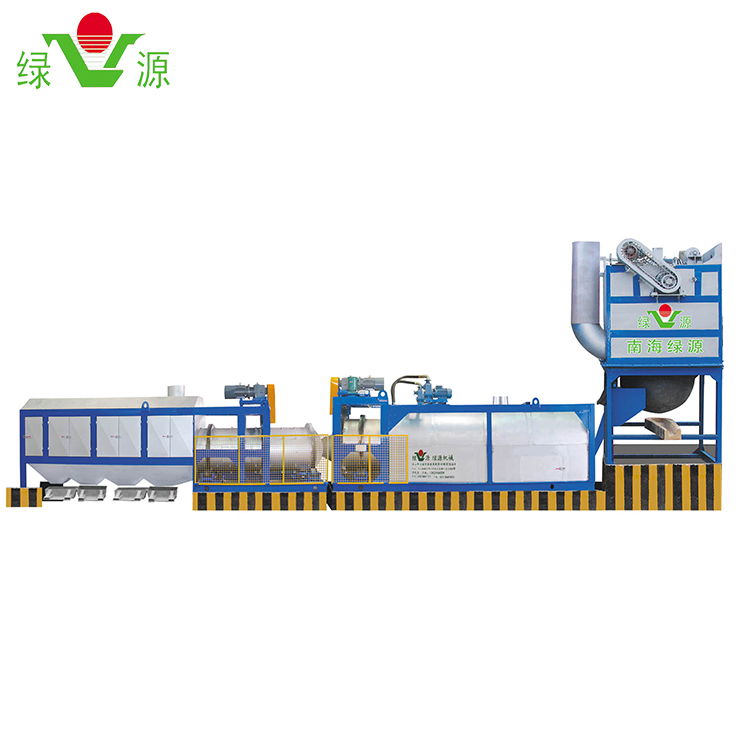

The aluminum dross separator is a mechanical device that introduces advanced foreign technology,does not require fuel, and can quickly recover aluminum dross with high aluminum content. It thusreplaces the traditional manual ash roasting method. With the aluminum dross separator, aluminum canbe processed and separated in one go on the furnace site, and it has the characteristics of highaluminum recovery rate, short time, low power consumption and environmental protection. Main production models :LY 50, LY 70, LY 90, LY 110, LY 130, LY 150.Single processing capacity :50-1200KG(Customizable according to customer output) |

Pulse Bag Type Dust Collector

|

Special Concrete Structure Pulse Bag Type Dust Collector

|

The physical and chemical properties of industrial dust are different,and the nature and degree of harm to the human body are different.The pulse bag filter developed by our company based on the basic concept of protecting labor safety and healthy production is a kind of widely used The dus t removal sys tem ensures more thorough dus t removal,finer filtration, and more convenient maintenance without changing the physical characteristics of the dust.It has been applied to all walks of life and is suitable for metallurgy , building material , cement,machinery and chemical engineering,electricity,The purification of dust and gas and the recovery of materials in the light industry | In response to the special characteristics of flue gas in the smelting of recycled aluminum, recycled copper, and steel, our company has launched a concrete structure pulse bag filter. Advantages of dust collector application: 1.Durable and sturdy 2.Excellent corrosion resistance 3.Service life of over 30 years 4.Simple equipment maintenance 5.Stable equipment operation |

主营产品

MAIN PRODUCT

主营产品

Aluminum casting auxiliary materialsInstruction:After finishing the grilled slag, the small flame disappears. This slag directly and uniformly dispersed into the molten pool of Aluminum, which is appropriate to strengthen the artificial mixing, evenly spread. This is to ensure a certain diffusion time according to the actual situation.

| Fluxes Aluminum casting slagging agent.Use inside furnace:When aluminium is melt and heated up to casting temperature, spread de-cinder flux with shovel onto the slag face, then strike with steel rake lightly, mix aluminium slag for 3~5 minutes, then skim the slag finally.

| High quality Aluminium refine agent/Aluminum Refining FluxInstruction:After finishing the grilled slag, the small flame disappears. This slag directly and uniformly dispersed into the molten pool of Aluminum, which is appropriate to strengthen the artificial mixing, evenly spread.

| Aluminium Melting Refining Flux Slag Removing AgentInstruction:After finishing the grilled slag, the small flame disappears. This slag directly and uniformly dispersed into the molten pool of Aluminum, which is appropriate to strengthen the artificial mixing, evenly spread. This is to ensure a certain diffusion time according to the actual situation.

|

Aluminum Ingot Casting Line

Casting Furnace Workshop

LVYUAN NEWSLVYUAN NEWS |

Our products

aluminum sandblasting machine, aluminum automatic interruption saw, traction machine;

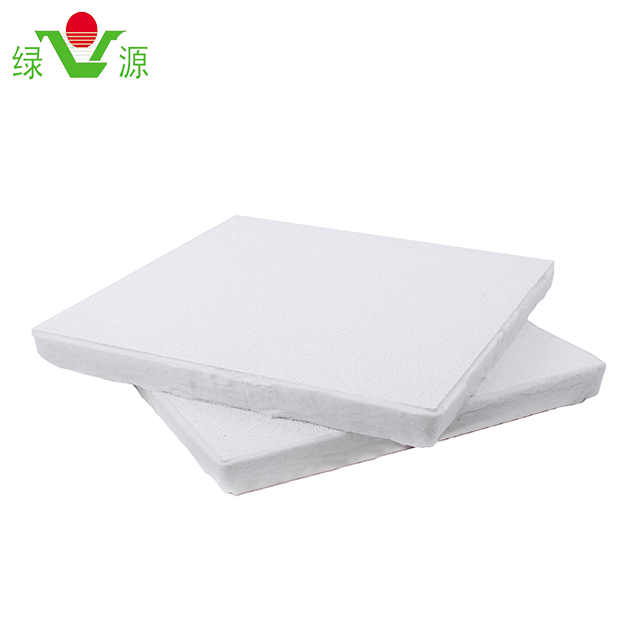

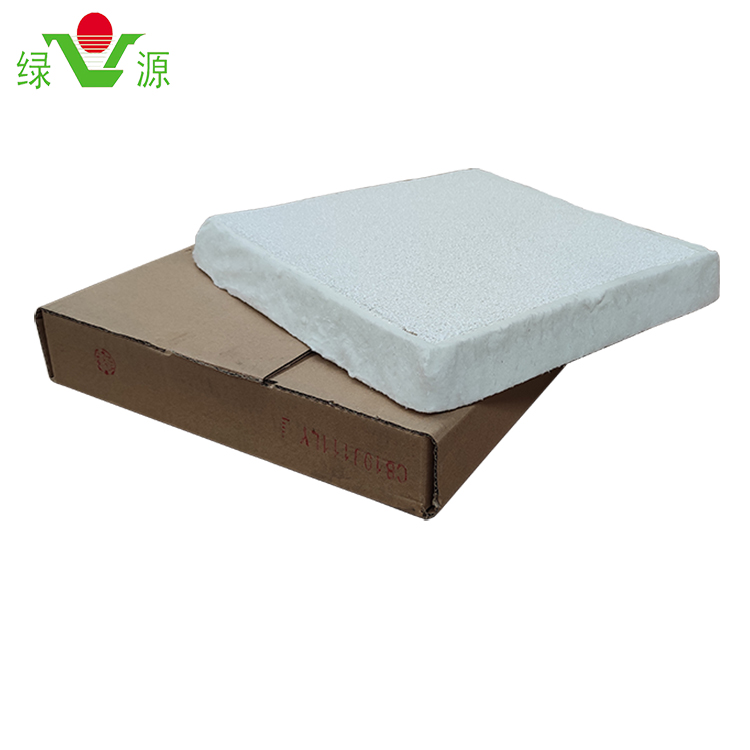

aluminum-silicon alloy ingots, ADC12 and various brands of alloy; ceramic filter plate;

High-voltage electrostatic dust removal equipment, aluminum melting furnace,

the use of waste heat rotary dryer, aluminum conveyor belt;

Aluminum (zinc) ash cooling ball mill separator, aluminum ash recycling production line casting equipment,

flux and elemental additives;